Remote-Controlled Axial Flux Motor

A hands-on project involving the design, fabrication, and testing of a custom electric motor.

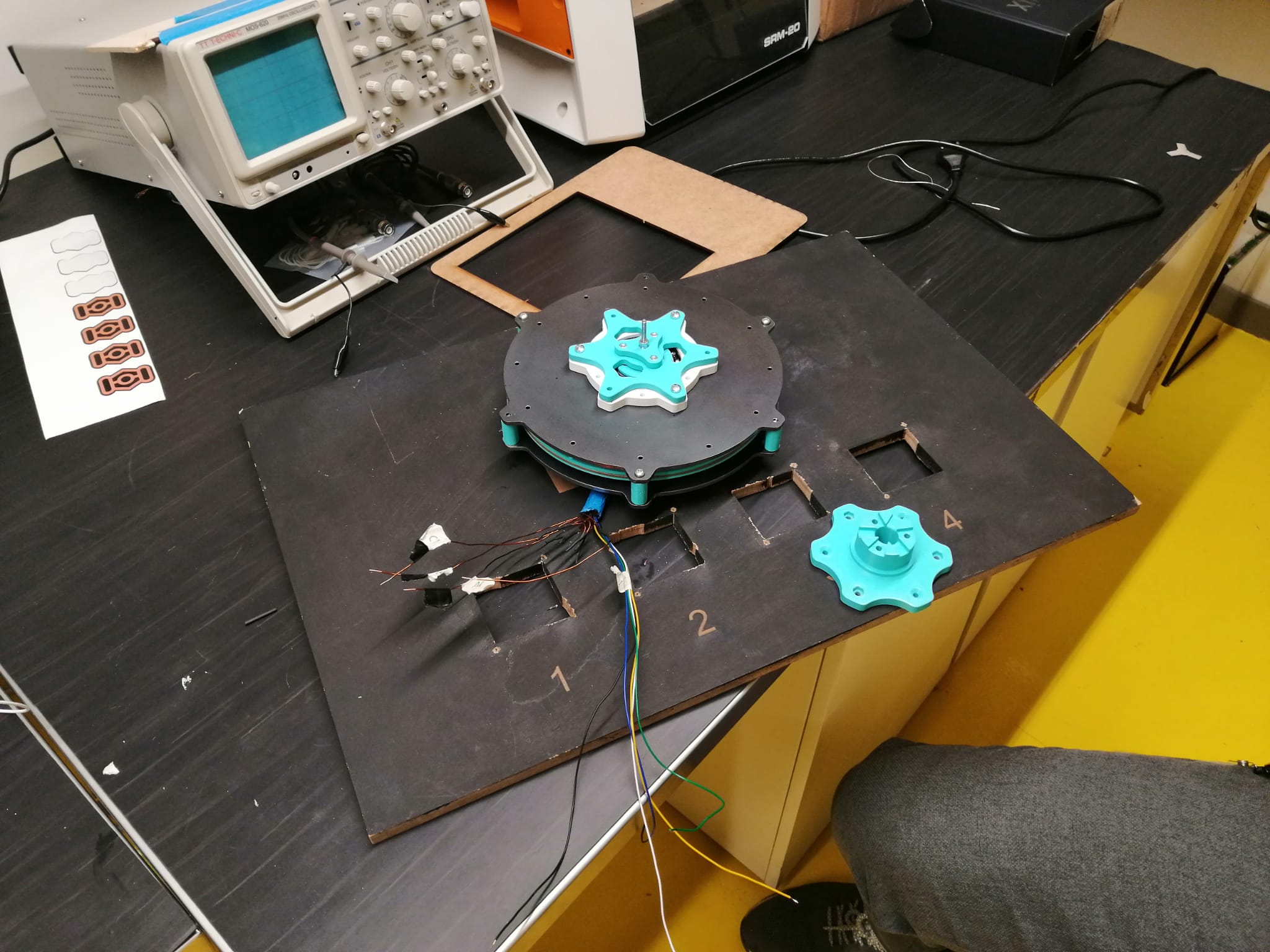

Overall view of the completed motor prototype.

Project Overview

This project involved the complete lifecycle of creating a custom electric axial flux motor. The primary goal was to design a motor from scratch, fabricate its components including hand-wiring the coils, and integrate a remote control system using NRF24L01 transceivers for wireless operation. This endeavor aimed to provide practical experience in motor design principles, 3D printing for custom parts, and embedded systems programming for control.

The axial flux topology was chosen for its potential for high torque density and compact form factor. The project served as an excellent learning platform for understanding electromagnetic principles, material selection, and the challenges of manual fabrication processes.

Key Features & Technologies

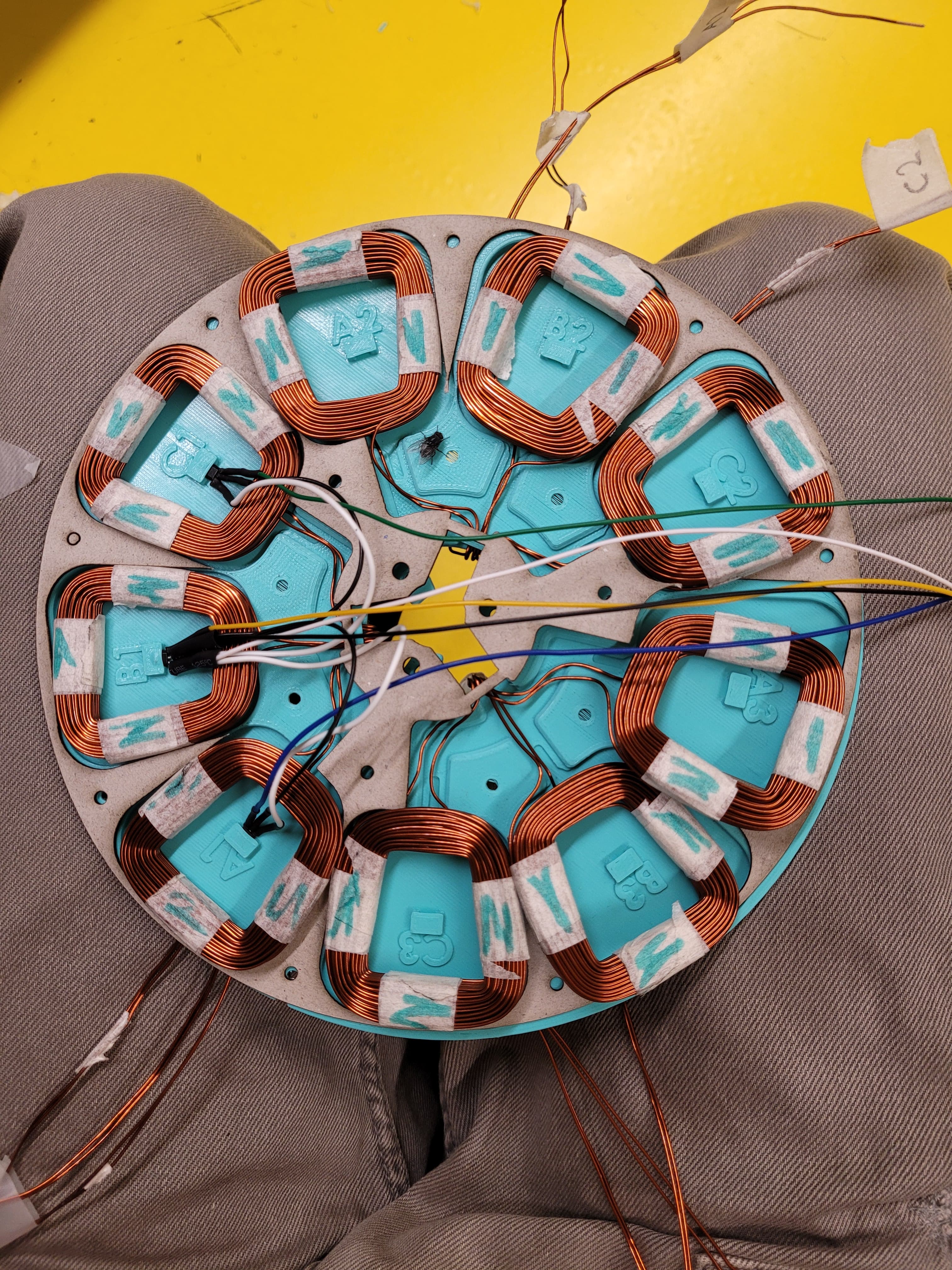

- Custom Motor Design: Designed an axial flux permanent magnet (AFPM) motor, including stator and rotor geometry, magnet placement, and coil winding specifications.

- Hand-Wired Coils: Manually wound copper coils for the stator, providing a deep understanding of motor construction.

- 3D Printed Components: Utilized 3D printing (e.g., FDM with PLA/PETG) to create custom motor housing, rotor, and stator supports.

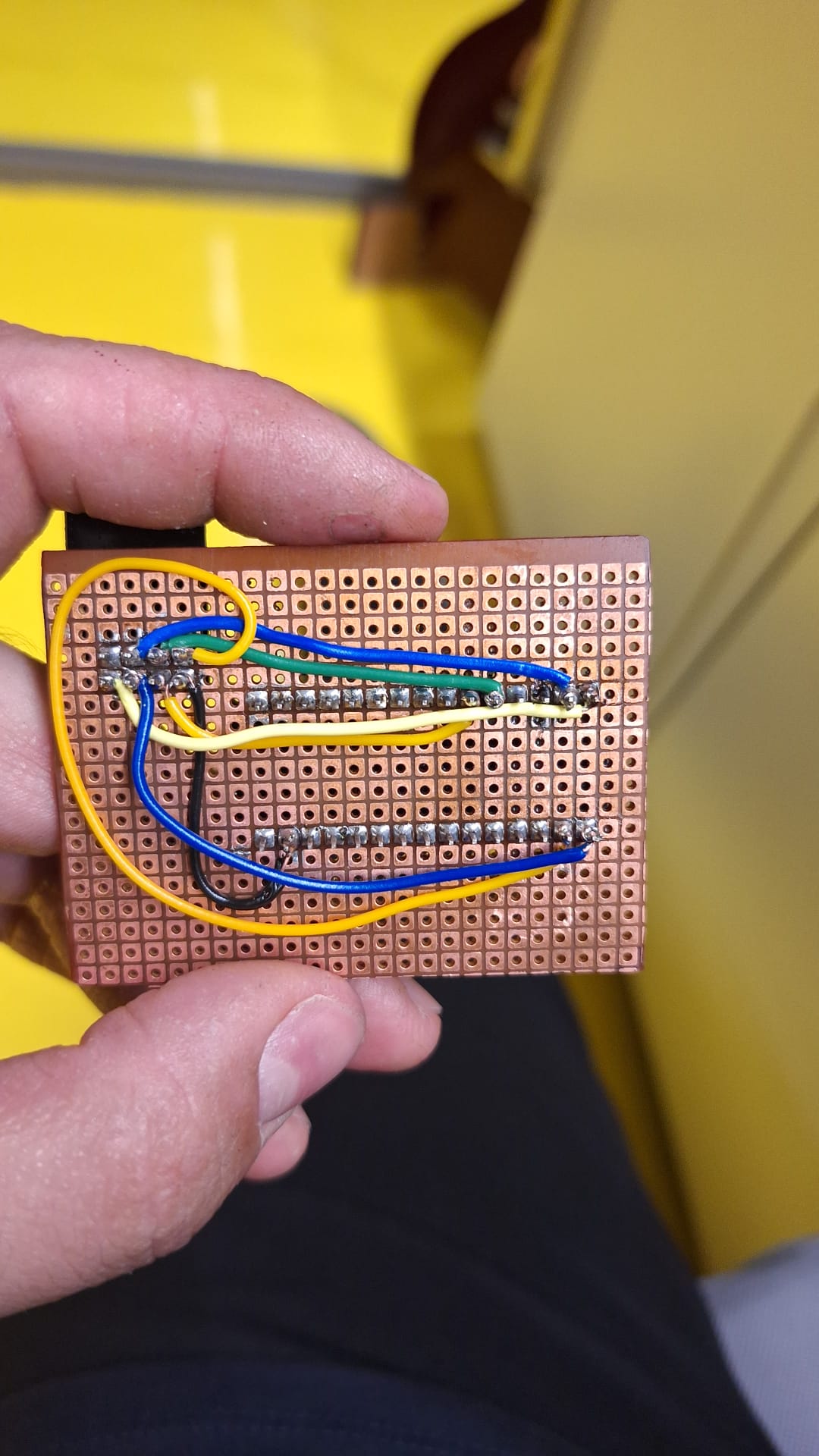

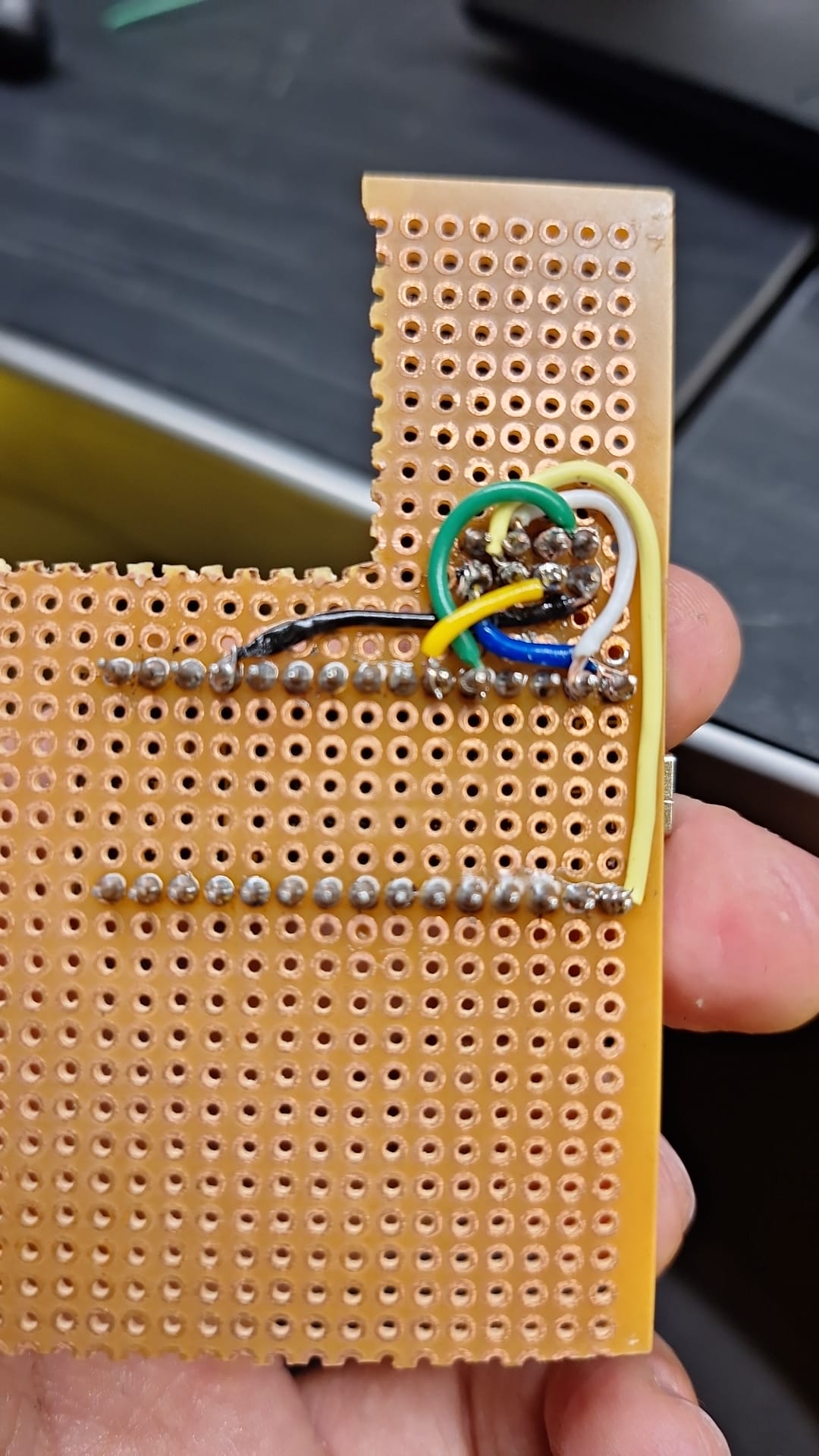

- NRF24 Remote Control: Implemented a wireless remote control system using Arduino microcontrollers and NRF24L01+ transceiver modules for motor speed and direction control.

- Custom PCB: Designed a compact PCB using KiCad for the motor driver and NRF24 module integration.

-

Technologies Used:

- Microcontrollers: Arduino (e.g., Nano, Uno)

- Wireless Communication: NRF24L01+

- CAD Software: Autodesk Fusion 360, SolidWorks

- Slicing Software: Cura, PrusaSlicer

- Programming: Arduino C/C++

- Motor Control: L298N motor driver, Custom ESC (if applicable)

Challenges & Solutions

During the project, several challenges were encountered and addressed:

- Challenge: Achieving precise alignment of the rotor and stator with 3D printed parts, critical for optimal motor performance.

Solution: Implemented an iterative design process for the 3D models, incorporating adjustable mounting points and developing calibration jigs to ensure accurate assembly. - Challenge: Ensuring reliable wireless communication with the NRF24 modules, especially in environments with potential RF interference.

Solution: Developed a robust communication protocol with error checking and retransmission capabilities. Careful antenna placement and power supply decoupling for the NRF24 modules also improved signal integrity. - Challenge: Overheating of motor driver components (e.g., L298N) when operating the motor at higher loads or for extended periods.

Solution: Integrated heat sinks onto the motor driver IC and implemented current monitoring in the Arduino code to trigger a fault state or reduce power if overcurrent conditions were detected. - Challenge: Optimizing the hand-winding process for the stator coils to achieve consistency and desired electrical characteristics.

Solution: Created winding guides and templates using 3D printing, and meticulously counted turns and ensured uniform tension during the winding process.

Visual Gallery

A collection of images showcasing the design, components, and assembly process of the remote-controlled axial flux motor.

Presentation Slides

For a more detailed overview, including design considerations and testing results, please view the project presentation slides embedded below.

Outcomes & Learning

The project successfully resulted in a functional remote-controlled axial flux motor prototype that demonstrated the viability of the custom design and fabrication approach. Key learnings included a deeper understanding of electromagnetic field interactions within axial flux machines, and the nuances of implementing reliable wireless data transmission for real-time control applications. This project significantly enhanced my skills in iterative design, circuit integration, and hands-on fabrication techniques. It also provided valuable insights into importance of systematic testing and debugging.